Long service life

Lightweight components reduce the load of crossing, so as to reduce the fault margin of the robot and achieve a longer life of the robot. The solenoid valve group is completely sealed to avoid oil pollution and dust erosion and increase its service life.

High safety

There is no air joint in the terminal wiring of electronic control line to avoid bad contact due to joint corrosion. Inspection switch and anti-drop device are attached to the lower position of arm with high safety.

Wide applicability

Multi-point positioning can be realized by external crossing, which can be used for different requirements of the following processes.

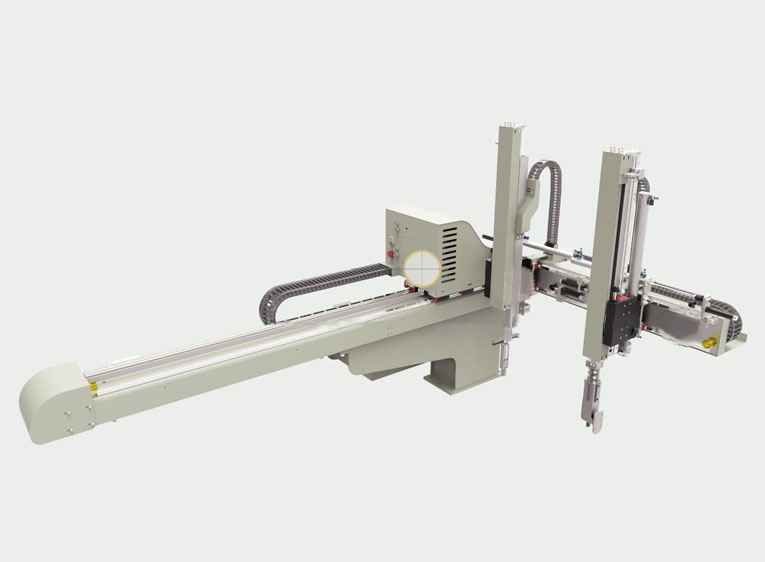

Aluminum Alloy Form Structure design

Integrated Forming Aluminum Profile Technology

Single axis AC servo

With built-in single axis AC servo, close-loop type control aeration mechanism, instructed free editing program is easy to operate. It has the multilingual menu type true color touch screen operation interface.

Double-section type up and down movement

Double-section type up and down movement, it adopts double speed mechanism with fast speed, which is adapt to the low workshop design.

Single axis and double sections

MODEL | Arm Type | Applicable molding machine | YM1 | YM2 | Y | X1 | X2 | X3 | X4 | X5 | Z | H | HS | Maximum load Include fixture (KG) |

A650IDY | Single section | 50-150 | 190 | 460 | 650 | 680 | 170 | 130 | 120 | 120 | 1180 | 1270 | 685 | 5 |

A750IDY | Single section | 150-200 | 190 | 560 | 750 | 680 | 170 | 130 | 120 | 120 | 1380 | 1370 | 685 | 5 |

A850WDY | Double section (Double speed type) | 160-250 | 160 | 690 | 850 | 800 | 170 | 230 | 120 | 130 | 1560 | 1250 | 785 | 5 |

A950WDY | Double section (Double speed type) | 200-350 | 160 | 790 | 950 | 800 | 170 | 230 | 120 | 130 | 1750 | 1270 | 785 | 5 |

Relevant application fields

Repeat Precision±0.1 | Load≤5KG | Empty Cycle Period≤9S |

Links

Links